Xuzhou Weiser Water Affair Science & Technology Co.,Ltd.

Welcome to the official website of the international joint! Wall mounted air system Kinghonor winsis professional, central fresh air system, fresh air system cabinet,

Fresh air machine, indoor air cleaner manufacturer, household fresh air system brand. Winsis intelligent health air system leader, service hotline: 4006-466-968

- Water level gauge series

- Pluviometer series

- Gate level gauge series

- Evaporation station series

- Display instrument series

- Flow velocity series

- Flood warning series

- Groundwater monitoring equipment

- Gate control system

- Pumping station control system

- Geological disaster prevention

- Dam monitoring system

- Water regime measuring and reporting system

- Telemetry terminal products

- Soil moisture monitoring system

- Agricultural well irrigation control system

- Groundwater level automatic monitoring system

Contact information |

Weiser Water Technology

Contact: manager ZhangMobile phone£º18952121514 Fax: 0516-83859755 Email/skype£ºzhangwei@weiser.cn Website£ºhttp://www.weiser.cn Address: 4th floor,C2-A,Xuzhou Software Park,East Jinshan Road,Xuzhou City,Jiangsu Province,China |

Product display |

¡ú Dam monitoring system |

Reservoir dam safety monitoring system |

|

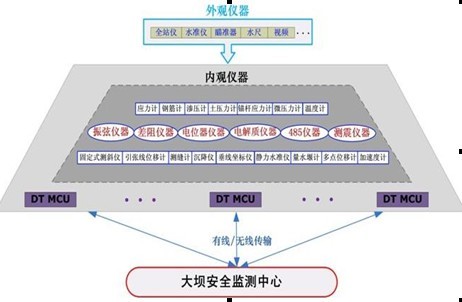

Xuzhou Weisi Water Technology Co., the company has a large number of communication, automatic control, hydrology and water resources, water field technical backbone industry, construction has large and medium-sized reservoir dam safety monitoring system development work, with rich practical experience in the engineering application of dam safety monitoring system of hydropower station reservoir area. 1. monitoring contents, methods and instruments The 1.1. dam area, rainfall intensity and rainfall monitoring: the tipping bucket rainfall and rainfall intensity measurement. Seepage line and dam foundation seepage monitoring of 1.2. dam: monitoring seepage pressure distribution and seepage line position of dam and seepage pressure distribution of dam foundation by observing embedded pressure gauge. Water level monitoring at upper and lower reaches of 1.3. dam: Observation of upstream and downstream water level by installing float type and vibrating string type water level gauge. 1.4. dam displacement monitoring: the total station automatic polar coordinate measuring system is used to monitor the dam deformation, and the integrated engineering measurement system can realize unattended and automatic monitoring. 1.5. dam seepage monitoring: a weir is installed downstream of the dam, and the weir is installed to monitor the dam seepage. 2. sensor: according to the actual needs, in the monitoring range to install a variety of sensors. Commonly used are: osmometer, concrete strain gauge, stress meter, multi-point displacement meter, joint meter, water gauge, inclinometer, gauges, dynamometer, barometer, thermometer, pressure box etc.. 3. automatic monitoring system Brief introduction of 3.1. system With the development of computer technology and electrical measurement technology, the monitoring project based on electric sensor technology can realize all-weather automatic monitoring. Similarly, the monitoring system also has the artificial observation condition, through the observation personnel to carry the reading instrument or the notebook computer to read the data to each monitoring station, and may enter the related database by the manual input computer. Continuous automatic monitoring can record the complete data change process of the monitoring object, and obtain data in real time. With the help of computer network system, the data can be transmitted to any department which needs the data within the network coverage. 3.2. system composition The system consists of three parts: 1) field measurement part 2) remote terminal acquisition unit MCU 3) data processing part of Management Center Network structure of 3.3. system The dam safety monitoring data acquisition system adopts hierarchical distributed open type structure, operation mode for decentralized control, can be ordered each on-site monitoring unit according to the set time automatically monitoring, data storage, and to submit the data safety monitoring center. The network communication between the system MCU and the MCU and the monitoring computer adopts the optical fiber cable. The safety monitoring data acquisition system can collect the monitoring data in each monitoring station of the project through optical cable, and then transmit it to the monitoring host in the monitoring center of the management station through optical fiber cable. 4. monitoring system functional features The monitoring system is designed to provide the best solution for dam safety monitoring: 4.1. can monitor the test parameters of the dam in real time and can set the acquisition frequency and measurement point data according to the requirements, and the original data can be calculated in various ways. 4.2. can be used for professional evaluation of reservoir dam collection data, according to the requirements of water conservancy professional related data calculation, evaluation and processing, in order to meet the needs of various evaluation models. 4.3. data can be stored in various database forms and can be used for historical data query, and EXCEL or other forms of reports can be generated directly. At the same time, the data can be stored in the webpage report in real time, providing web pages to browse various data remotely. 4.4. data can be displayed graphically, including time history curve diagram, X/Y coordinate map, simulation chart, histogram and so on. 4.5. has data more limited alarm function, when the scene upload alarm information, the host will appear obvious alarm picture and alarm information, at the same time can also provide a variety of sound and light alarm and other multimedia tips. 4.6. realizes the printing function of the system information, supports the printing of graphics, reports, curves, alarm information, various statistical calculation results and so on. 4.7. online editing, maintenance, modification, expansion function. The system hardware and software meet the requirements of open standards, and meet the requirements of the system in the hardware node increase, database capacity expansion, system software function and so on. |

The official WeChat

|

Copyright © 2017 Xuzhou Weiser Water Affair Science & Technology Co.,Ltd. All Rights Reserved¡¡Web Design£ºXZDELI.COM

|

Official WeChat

Official WeChat Mobile website

Mobile website